Revolutionizing Water Purification

Continuous Ultra Filtration

A single operation delivering complete purification, zero liquid discharge, and unmatched performance for municipal, industrial, and commercial applications

ZLD

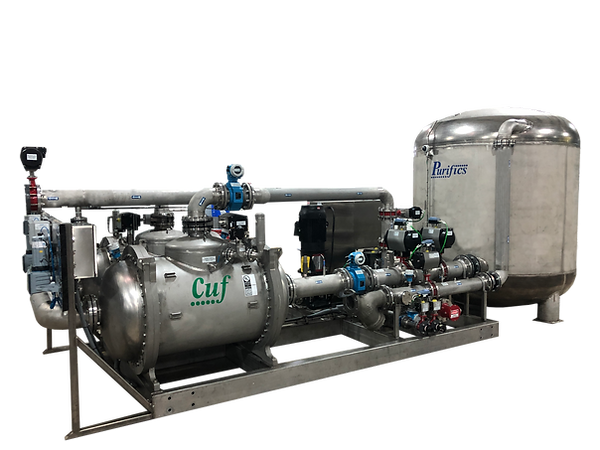

A high-performance continuous ultra-filtration process that combines concentrated sweep floc with SiC ceramic membranes to remove multiple contaminants in a single platform. Cuf ® draws water directly from the source and delivers 100% purified water.

This advanced technology minimizes footprint, operational complexity and chemical use, while eliminating the need for pre-treatment & membrane replacement.

Unique Benefits

Complete Purification

Treats a wide range of contaminants in one system.

Scalable & Compact

Meets demand from small facilities to multiple MGD.

Low Lifecycle Cost

Significantly reduces plant footprint, complexity and chemical use.

Operator Friendly

Simplified maintenance, fully automated with remote access.

Sustainable Technology

Zero Liquid Discharge, and lowest carbon footprint.

Applications

Drinking Water

Surface, Groundwater, PFAS Destruction.

Industrial Water

Oil, Gas, Marine, Food & Beverage.

Reuse/Recharge

RO Pre-treatment, Wastewater, cooling tower recycling.

How It Works (Step-By-Step)

Smart Design. High Performance. Continuous Operation.

-

Source Water Intake (Surface/ Groundwater)

Raw water is first screened for what we call “frogs and logs” to protect downstream components.

-

Concentrated Sweep Floc Coagulation

A small dose of coagulant is injected into the In-Situ Reactor (ISR), where solids are concentrated up to 100 times. This creates a highly concentrated sweep floc that captures contaminants during the process. The higher the solids concentration, the greater the performance of surface-mediated reactions, making the system ideal for purifying even in challenging water conditions.

-

Crossflow Filtration and Flux Regulation

Water flows across robust silicon carbide (SiC) membranes in a crossflow pattern, removing contaminants while minimizing buildup. The system achieves high flux rates (250 to 500 GFD, depending on the application) and maintains consistent performance through active transmembrane pressure (TMP) control, ensuring reliable operation under changing water conditions.

-

Self-Cleaning via Dynamic Shock

The system operates continuously by applying dynamic shocks that travel through the membrane module to clear built-up solids and prevent fouling. This self-cleaning process enables high-efficiency performance with minimal maintenance, eliminating the need for regular shutdowns and membrane replacements.

-

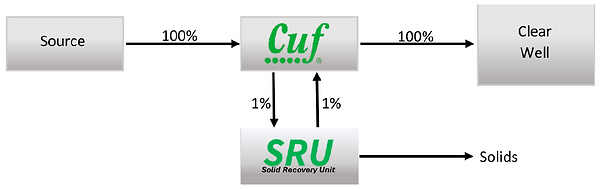

Zero Liquid Discharge

A concentrate slipstream is sent to the Solids Recovery Unit (SRU), where solids are efficiently recovered. 99.99% of the water is returned for purification. The SRU system is fully automated, chemical-free and requires no manual labour.

Zero Liquid Discharge

SRU

Solids Recovery Unit

Total Recovery. Total Efficiency 99.99%

The Solids Recovery Unit (SRU) is a fully automated, chemical-free system within the Cuf ® process that achieves true Zero Liquid Discharge (ZLD) with 99.99% water efficiency. Utilizing low-energy silicon carbide (SiC) flat plate membranes, the SRU recovers a wide range of solids, including coagulated organics, biomass, silt, algae, sludge, and precipitated metals, converting them into a manageable solid phase.

Designed for continuous or on-demand operation, the SRU provides a sustainable, long-life solution that enables the Cuf ® system to deliver complete water purification with zero waste. It can also function as a standalone unit or be integrated with other treatment processes.